21

Jun

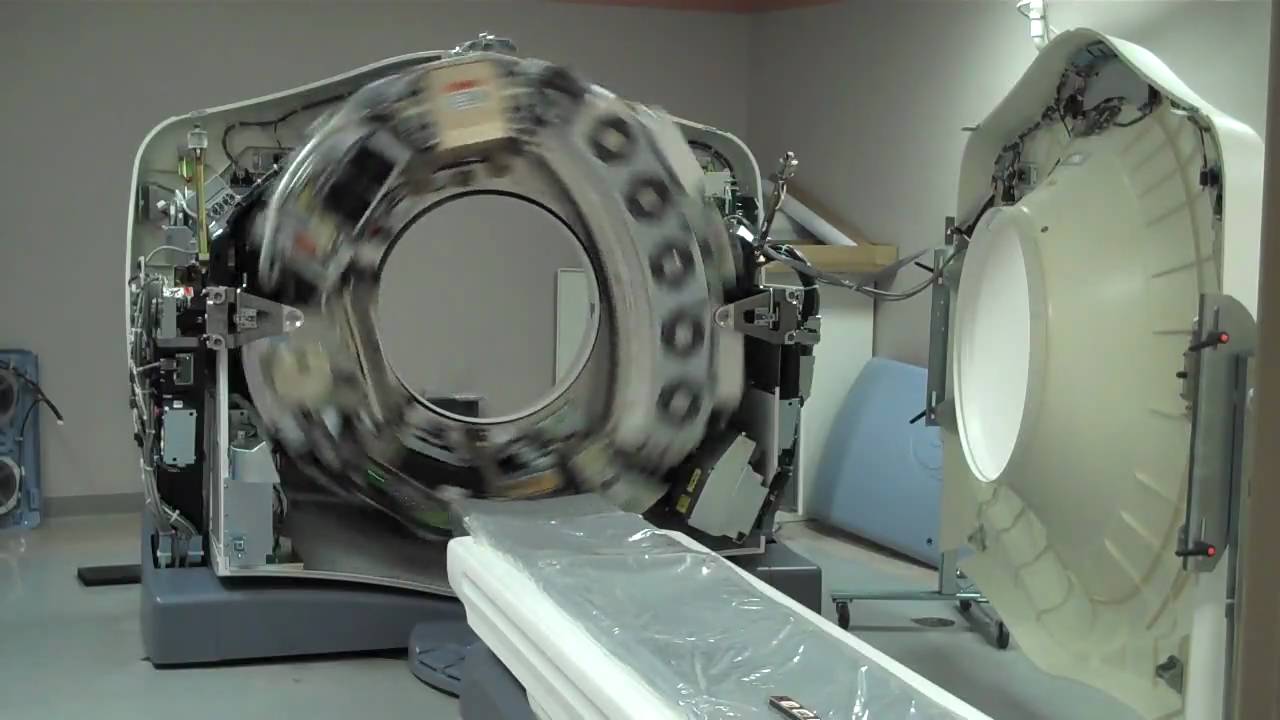

State-of-the-art medical diagnostic equipment has transformed the quality of care for our society. Non-invasive imaging of the interior of the body enables the surgeon to perform operations while minimizing damage to adjacent tissue and organs. The IGBT has been used since the early deployment of CT scanners for the control of the gantry on which the patient is reclining as described below. It is also used in the power supply for X-ray and Ultrasound machines. In addition, hundreds of thousands of lives are being saved due to the availability of portable defibrillators which require IGBTs for delivering the controlled shock to the patient of cardiac arrest as discussed below.

Computed tomography (CT) generates a three dimensional image of a patient using a large series of two dimensional images taken around a single axis of rotation. The image is generated by viewing the patient using x-ray imaging from numerous angles. A single plane of a patient is scanned from various angles in order to provide a cross-sectional image of the internal structure of that plane. A three-dimensional view can then be created by mathematical analysis that combines the images. The gantry on which the patient is reclining is positioned using closed loop feedback control of motors in order to accurately move and position the patient.

An IGBT-based motor drive is employed by all manufacturers, such as GE, Philips, and Siemens, for precise and controlled movement of the gantry. The CT scanner contains an X-ray tube with detectors located diametrically opposite the X-ray source which are rotated around the patient to generate a section image. CT scanners can provide detailed cross-sectional images of nearly every part of the human body including the brain, neck, shoulders, cervical spine, heart, lungs, abdomen, liver, kidney, pelvis, etc.